Welcome To Sunrise Ispat Udyog

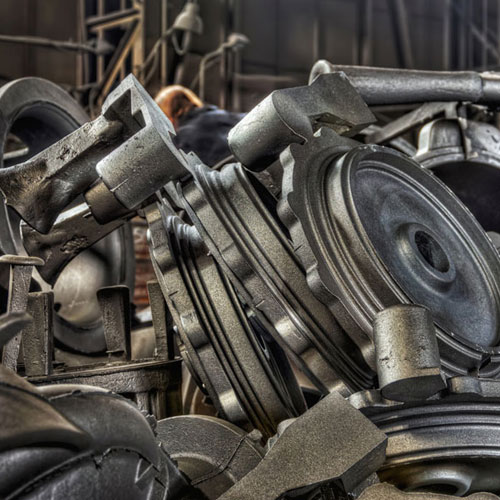

Established in 1997 by Mr. Vinod Kumar, & headquartered in Focal Point, MGG, Punjab, Sunrise Ispat Udyog is a well-established and highly regarded manufacturer of raw and machined castings in both sand and investment.

Sunrise Ispat Udyog is a prominent supplier to industries servicing the Chemical, Petrochemical, Pulp & Paper, Steel Rolling Mills, Food Processing markets with corrosion-resistant, high heat, and wear resistant steel, stainless steel & high alloy parts.

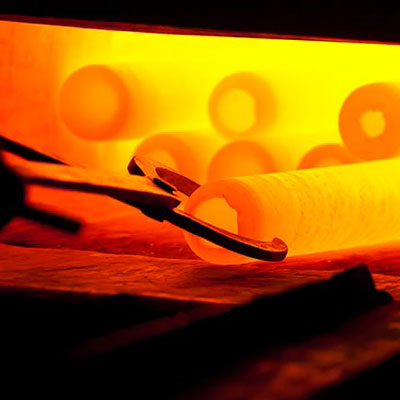

We are an ISO 9001:2015 certified division. Quality Management System is implemented at every stage of casting process – incoming, process control, post processing and final inspection. Qualified and dedicated team of inspection engineers lead the department for manufacture of flawless quality castings.